Have you ever seen a product and thought,

“I came up with that years ago!”?

Well, that doesn’t have to happen anymore.

What if you wanted to publish your own book, develop a software application, or put your company logo on an existing product? Well, there are many platforms that allow you to do that in a single pipeline.

But what if you wanted to create your own product? How do you do that?

Development of a physical product is an expensive, complicated process.

You need to design it, fund it, manufacture it, warehouse it, sell it, and then fulfill and ship it to the customer.

Either you need to learn all these steps yourself, or you need to hire individual professionals to do the work for you.

What if a single company could perform all the tasks needed to bring your idea from napkin sketch to finished product?

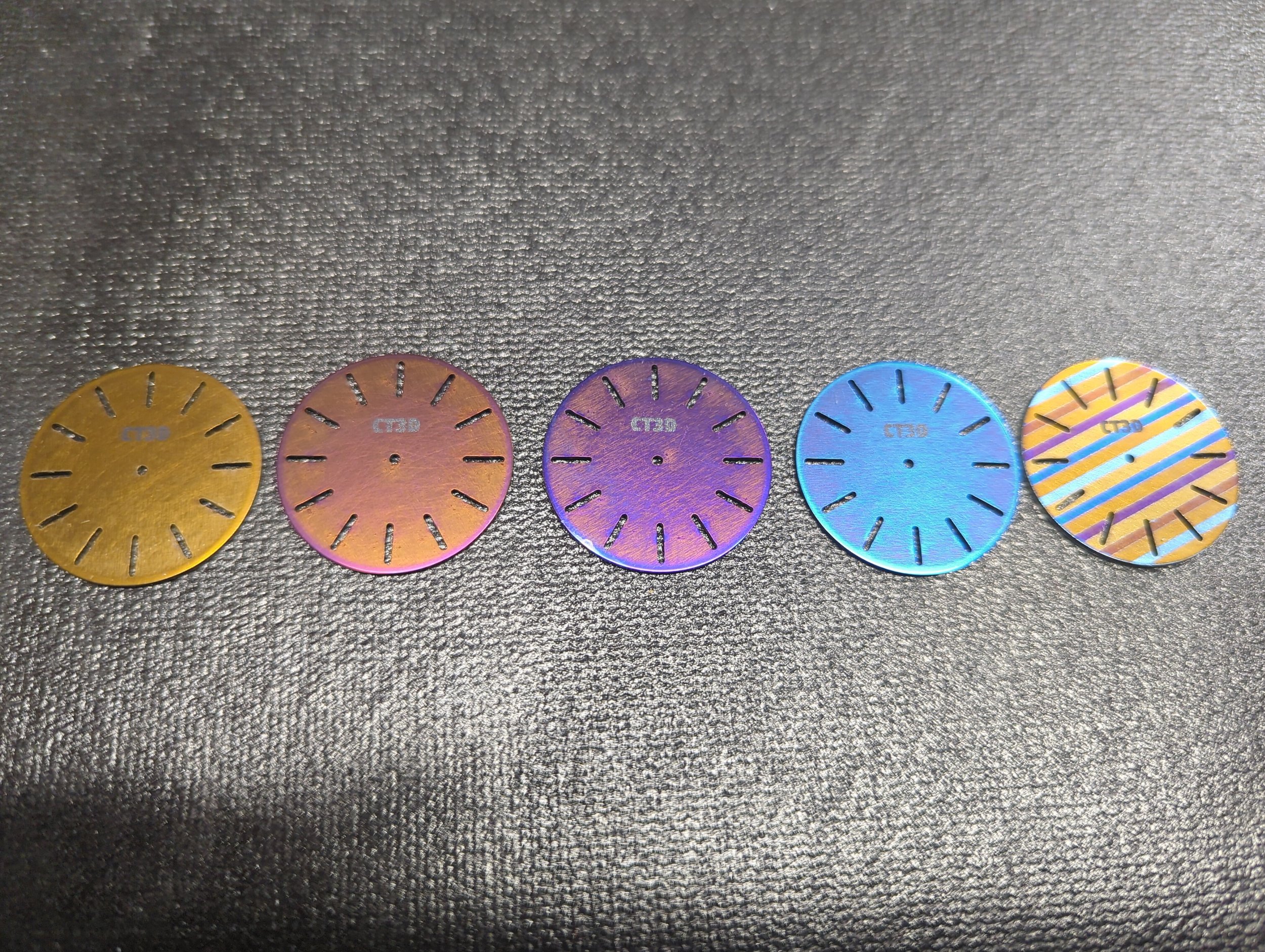

CT3D is that company, and we’re announcing the Turnkey Manufacturing Platform. A place where any designer, product developer, influencer, or Maker can bring their ideas.

CT3D will handle the manufacturing backend using advanced design, hybrid manufacturing, and on-demand production.

CT3D’s business model

Proof of Concept: We work with you to develop your idea from napkin sketch to physical prototype. Along the way, we also design the manufacturing process in parallel to the product design so that you don’t end up with a design that can’t be manufactured.

- Phase 1: A 3-month development cycle of a physical prototype, ending in a physical prototype that you have in-hand. You test it, bring it to shows, and get valuable customer feedback.

- Phase 2: CT3D incorporates all the design changes that you need, based on your usage as well as customer feedback into a revision 2 device (rev2). Then we fabricate a set of 3 - 5 rev2 devices that you give out to family, friends, influencers, or testers to get more feedback and critiques.

- Phase 3: CT3D makes all the design changes from Phase 2. The product is now ready for prime time, the manufacturing process is dialed in, and you’re ready to launch on a platform of your choice (Etsy, in-person retail, Amazon, etc).

Co-Development: CT3D has a deep bench of on-demand engineers, from electrical, design, and manufacturing engineers. No product is too complex or out of reach. CT3D hires these engineers to help co-develop the product and serves as a project manager for the team along the manufacturing development process.

Turnkey Manufacturing: CT3D offers low-volume fabrication of your product when you’re first starting out. This allows you to have a small stock on-hand, keeping inventory and upfront investment low. By designing the manufacturing process along with the product, if your device gets noticed and orders explode, we can seamlessly transition to mass production using on-demand manufacturing partners like FormLabs, SendCutSend, Slant3D, or Protolabs.

CT3D’s services:

Product ideation, design scope definition, preliminary design consultation, and ongoing design iteration.

Fabrication of physical prototypes (either CT3D’s design or your own design). CT3D uses a combination of off-the-shelf products, 2D laser cut sheet stock, 3D printed parts (plastic or metal), and CNC machined components (plastic or metal).

Low-volume manufacturing of physical products: Keep your inventory low by using CT3D’s on-demand manufacturing platform.

Re-shoring of legacy items. Let CT3D help you bring your manufacturing back to the USA!

Large-format 3D printing: Offering one of the few print-as-a-service bureaus in CT that offer large format FDM printing utilizing the Modix BIG60 FDM platform. Parts up to 24” x 24” x 26” (600mm x 600mm x 660mm).